Aluminum Foundry advancements which support modern engineering solutions

Wiki Article

Top Factors Aluminum Factory Casting Is Thought About Eco-Efficient and Lasting and eco-efficient

Aluminum foundry spreading has actually arised as a leading method for sustainable manufacturing. Its high recyclability establishes it apart, enabling indefinite reuse with minimal energy expenses. The production process is designed to be energy-efficient, adding to a significantly reduced carbon impact. On top of that, improvements in innovation have actually resulted in reduced waste generation. These factors, in addition to the assistance for round economic situation concepts, elevate vital inquiries about the future of this eco-efficient technique.High Recyclability of Light Weight Aluminum

Light weight aluminum's high recyclability stands as a foundation of its sustainability profile. This metal can be recycled forever without shedding its necessary homes, making it an indispensable component of a circular economy. Around 75% of light weight aluminum ever before generated is still in operation today, showcasing its durability and reusability - Aluminum Casting. The reusing process requires just 5% of the energy required for main aluminum manufacturing, significantly lowering carbon exhausts and source exhaustionReusing aluminum also saves all-natural resources, lessening the demand for bauxite removal, which can be ecologically damaging. On top of that, the recycled light weight aluminum can be transformed right into new items, varying from beverage cans to auto elements, thereby sustaining different sectors. As customer recognition of ecological concerns expands, the demand for recycled aluminum is expected to increase, encouraging more efficient practices. Overall, the high recyclability of aluminum not just improves its sustainability however likewise paves the way for a more accountable approach to resource administration.

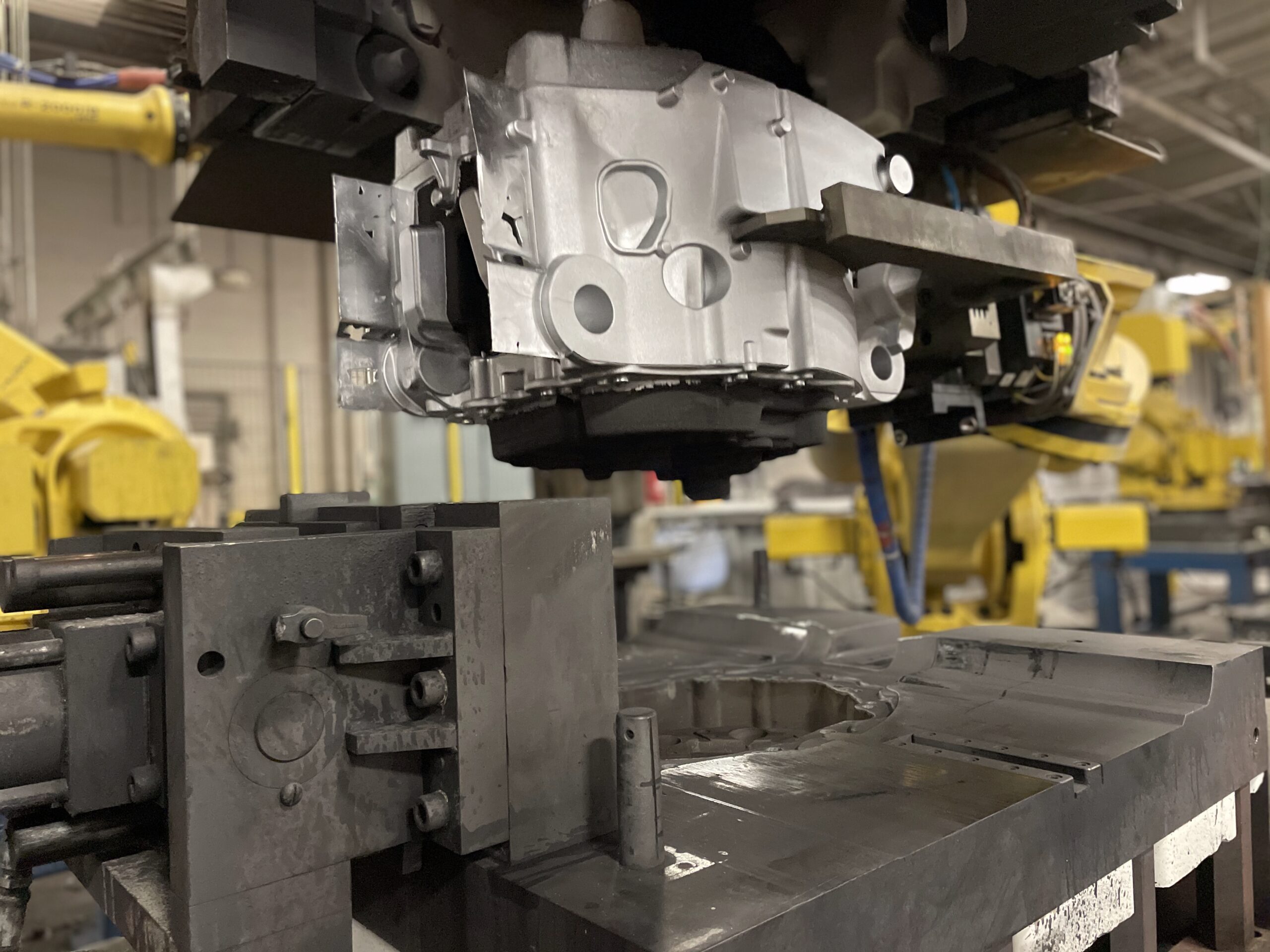

Power Performance in Production

A significant element of light weight aluminum foundry casting is its concentrate on power performance in production processes. Making use of innovative innovations, such as die spreading and investment casting, enables for specific control over the material and power inputs required. These techniques lessen waste and maximize the melting and casting cycles, decreasing general power intake.In addition, modern factories employ insulation techniques to keep warm during the melting procedure, better boosting power efficiency - Aluminum Foundry. The integration of sustainable energy resources, such as solar and wind power, is becoming increasingly usual, adding to a much more lasting production atmosphere

Decreased Carbon Impact

Energy efficiency not just enhances manufacturing procedures however additionally plays a considerable duty in decreasing the carbon impact of aluminum foundry spreading. The adoption of advanced modern technologies, such as energy-efficient heaters and maximized melting methods, lessens energy usage, which straight correlates with lower greenhouse gas discharges. This shift not just supports ecological objectives however likewise contributes to the sustainability of industrial procedures.Moreover, aluminum foundry casting typically uses recycled aluminum, which requires considerably much less power compared to creating brand-new steel from resources. This recycling procedure even more lessens the general carbon impact related to light weight aluminum manufacturing. Additionally, makers are increasingly focusing on eco-friendly power sources, such as solar or wind power, to meet their energy needs, more reducing reliance on fossil fuels. By prioritizing these eco-efficient methods, the light weight aluminum shop industry can substantially contribute to an extra sustainable future while dealing with environment modification issues.

Lower Waste Generation

In the search of eco-efficient aluminum shop casting, decreasing material waste is critical. By using recyclable steel and executing reliable production procedures, foundries can considerably decrease waste generation. This technique not only saves sources but additionally boosts overall sustainability in the spreading sector.Minimal Material Waste

While working in the direction of sustainability, the light weight aluminum foundry industry focuses on minimal product waste as a crucial purpose. This approach includes maximizing the design and production processes to reduce excess material throughout manufacturing. Advanced modeling methods and computer-aided layout permit accurate calculations, ensuring that every piece of aluminum serves a function. In addition, foundries execute efficient mold layouts that make best use of the utilization of light weight aluminum while minimizing scrap. By employing rigorous quality assurance steps, problems can be identified early, additional decreasing product waste. The adoption of lean manufacturing concepts encourages continual renovation, cultivating a society of waste decrease throughout the production cycle. Eventually, these methods not only enhance operational efficiency yet additionally add to an extra sustainable production atmosphere in the aluminum factory industry.Recyclable Metal Usage

Effective Production Procedures

Efficient manufacturing procedures are vital for reducing waste generation in aluminum factories, as they straight influence resource use and environmental sustainability. By taking on sophisticated production methods, foundries can considerably minimize scrap rates and power consumption. Strategies such as lean manufacturing and just-in-time manufacturing enhance operations, enabling perfect usage of raw products and minimizing excess supply. Furthermore, the implementation of recycling and re-melting approaches ensures that any kind of surplus light weight aluminum is repurposed, even more lowering waste. Automation and accuracy in casting procedures also add to greater accuracy, minimizing the need for rework and connected waste. Ultimately, these efficient production processes not only boost the foundry's economic efficiency but also advertise an even more lasting method to light weight aluminum spreading.Lengthy Item Life Cycle

The lengthy product life cycle of light weight aluminum spreadings is primarily credited to their remarkable sturdiness and stamina. These features bring about a lowered regularity of substitutes, permitting more sustainable usage gradually. As a result, the durability of these products adds considerably to eco-efficiency in manufacturing processes.Longevity and Stamina

Resilience and toughness are vital factors in the lengthy item life cycle of aluminum spreadings. These homes ensure that aluminum parts can withstand severe settings, mechanical tensions, and temperature fluctuations without considerable destruction. The intrinsic resistance of aluminum to rust better boosts its longevity, making it appropriate for different applications, from automobile parts to structural elements in structures. Furthermore, the capability to keep architectural honesty with time reduces the likelihood of failures, which is essential in markets where safety is extremely important. The mix of these attributes leads to boosted reliability and efficiency, eventually adding to a much more lasting approach in production. Consequently, aluminum spreadings not only offer their designated objective properly yet likewise advertise resource effectiveness through their prolonged use.Lowered Replacement Frequency

A substantial benefit of aluminum castings is their lowered replacement frequency, which adds to a longer item life process. This long life is credited to the integral properties of aluminum, including its resistance to rust and wear. Unlike various other products that might deteriorate with time, aluminum preserves its architectural stability under numerous ecological problems. As a result, items made from light weight aluminum castings require less regular replacement, causing reduced resource consumption and waste generation. Additionally, the extended life cycle of light weight aluminum components means that fewer products require to be extracted and refined, additionally improving their eco-efficiency. This sustainability facet not just advantages suppliers but also lines up with growing environmental problems, promoting a round economic situation technique in industrial techniques.Support for Round Economic Climate Concepts

Assistance straight from the source for circular economy concepts is essential in the context of eco-efficient aluminum shop spreading. This strategy stresses the value of resource performance and waste decrease through the recycling and reuse of materials. Light weight aluminum shops actively participate in this version by using recycled light weight aluminum, which substantially reduces power intake and lessens environmental influence compared to key light weight aluminum production.The assimilation of round economic climate concepts allows shops to decrease their carbon impact while generating economic worth. By fostering a closed-loop system, where end-of-life light weight aluminum products are reintegrated right into the manufacturing process, shops add to sustainable resource administration.

In addition, the adoption of these concepts encourages technology in style and manufacturing, advertising longer-lasting items that need less sources. Consequently, eco-efficient aluminum factory casting aligns with worldwide sustainability objectives, eventually supporting a change in the direction of an extra resilient and sustainable economic climate.

Regularly Asked Concerns

How Does Light Weight Aluminum Casting Effect Citizen Ecosystems?

Light weight aluminum casting can affect regional communities by changing land usage, potentially affecting wild animals environments and water high quality. Liable practices can mitigate negative effects, promoting sustainability and decreasing environmental impacts in surrounding areas.What Are the Health And Wellness Benefits of Utilizing Light Weight Aluminum Products?

Aluminum products provide health and wellness benefits such as lightweight building lowering physical pressure, deterioration resistance decreasing poisonous direct exposure, and recyclability advertising environmental sustainability. Their usage can result in much safer, much more efficient living and working settings for people.Are There Any Downsides to Light Weight Aluminum Factory Casting?

Light weight aluminum factory spreading has disadvantages, consisting of energy-intensive processes, potential emissions throughout manufacturing, and the threat of ecological contamination. Additionally, incorrect recycling methods can lead to lose and resource deficiency, weakening sustainability efforts.How Does Light Weight Aluminum Spreading Compare to Various Other Materials?

Light weight aluminum casting usually offers a positive strength-to-weight ratio, rust resistance, and recyclability contrasted to products like steel and plastic. Its light-weight nature supplies benefits in numerous applications, improving efficiency and efficiency in numerous sectors.What Industries Benefit The Majority Of From Light Weight Aluminum Foundry Spreading?

The vehicle, aerospace, and building industries profit most from light weight aluminum foundry casting. Its light-weight homes enhance fuel performance in cars, while its toughness and adaptability satisfy requiring structural requirements in numerous applications, advertising advancement and sustainability.A significant element of light weight aluminum shop casting is its focus on power performance in manufacturing procedures. Energy efficiency not website here just boosts production processes yet also plays a significant function in reducing the carbon footprint of aluminum foundry casting. Aluminum factory spreading often uses recycled aluminum, which requires significantly much less power contrasted to generating new metal from raw products. In the quest of eco-efficient aluminum factory spreading, minimizing material waste is paramount. Light weight aluminum shop spreading has drawbacks, including energy-intensive processes, prospective emissions throughout production, and the threat of ecological contamination.

Report this wiki page